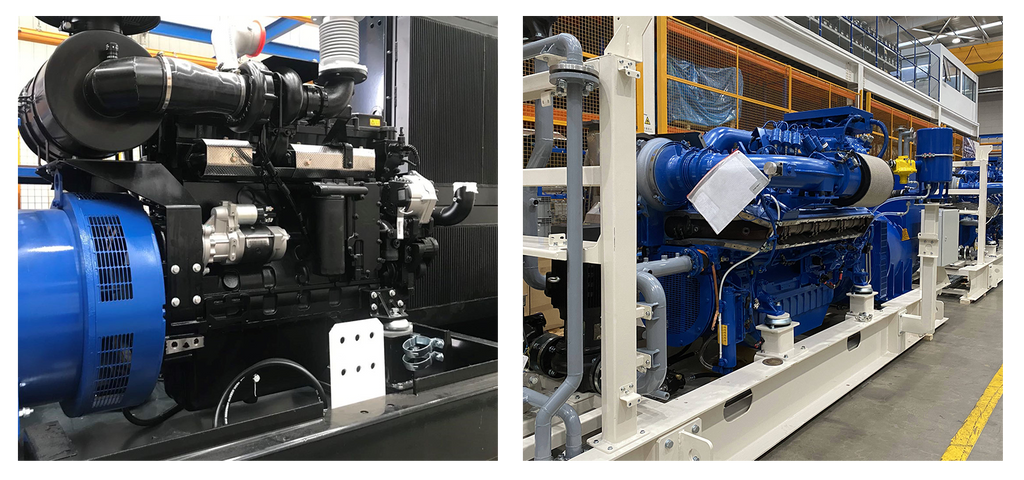

PowerLink Engine and Alternator

The T2 series of PowerLink engines and alternators are the most cost-effective engine and generator components in the world.

Based on their understanding and many years of experience of the applications of diesel generator sets for many years, and the professional requirements of global users, for diesel generator sets, we have developed the main components with ultra-high cost performance.

The PowerLink Engine, with a power range from 10KVA to 2500kVA, are completed by different factories.

With its unique power generation technology and service networks across different regions, the PowerLink Engine is not only designed and manufactured to meet the demands of the standby power market, but also designed and manufactured to meet the continuous operation conditions.

PowerLink Engine

Main features:

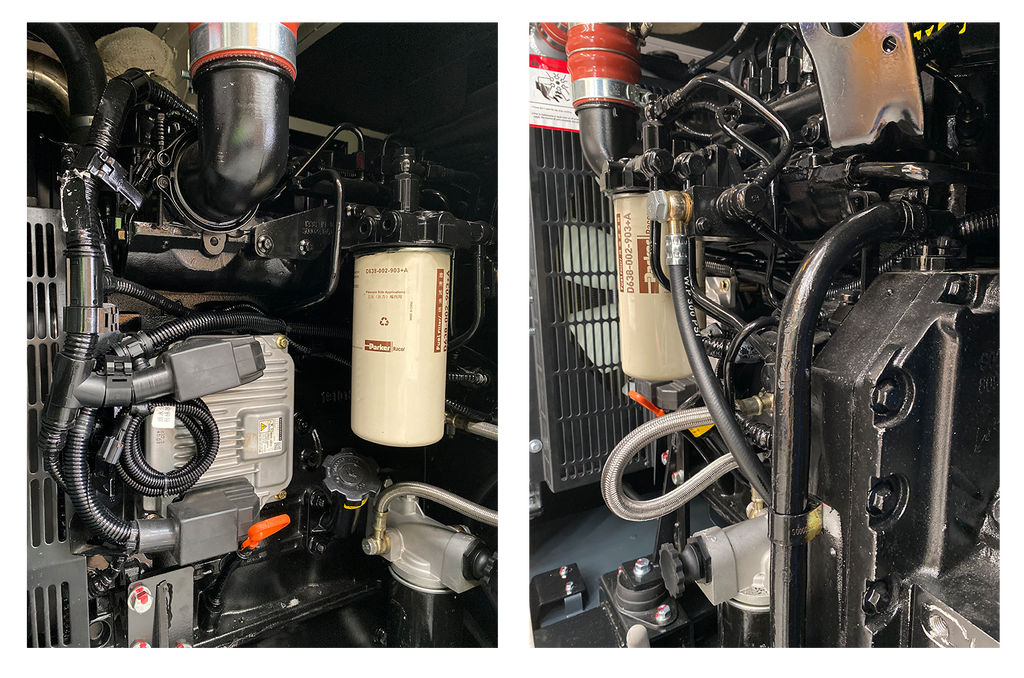

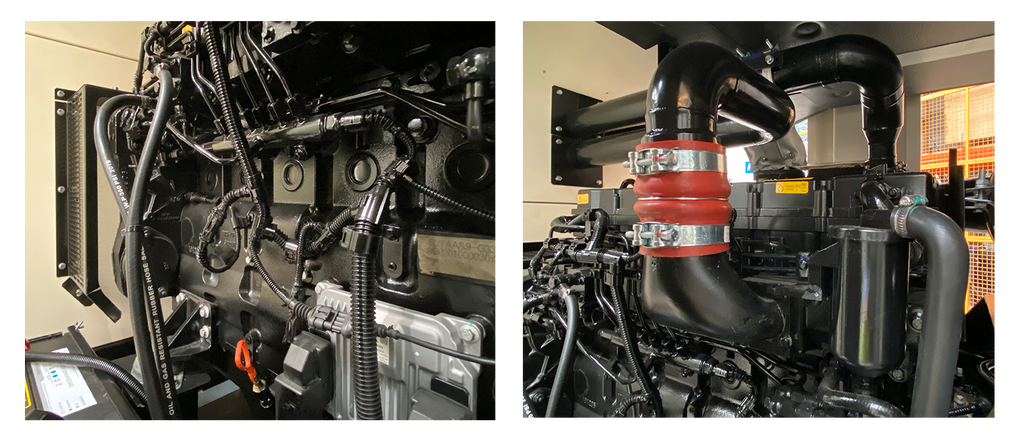

- Small size, light weight, compact structure, large host installation space, convenient maintenance

- All parts are processed by CNC equipment with high precision.

- Over 20000 hours of overhaul cycle historical data, stable and reliable operation.

- Electronic speed control, fuel saving and simple service.

- More than 10 years of operation data accumulation, to achieve the ultimate reliability, manufacturing technology, parameter calibration, cost control.

Engine Models:

- 3D1.4G1

- 4D2.3G1

- 4D2.7G1

- 4D3.2G1

- 4D3.2TG2

- 4D4.1TG2

- 4D4.1TAG2

- 4D4.1TAG3

Appearance baking paint, two-layer coating, wear resistance and scratch resistance, special anti-corrosion process.

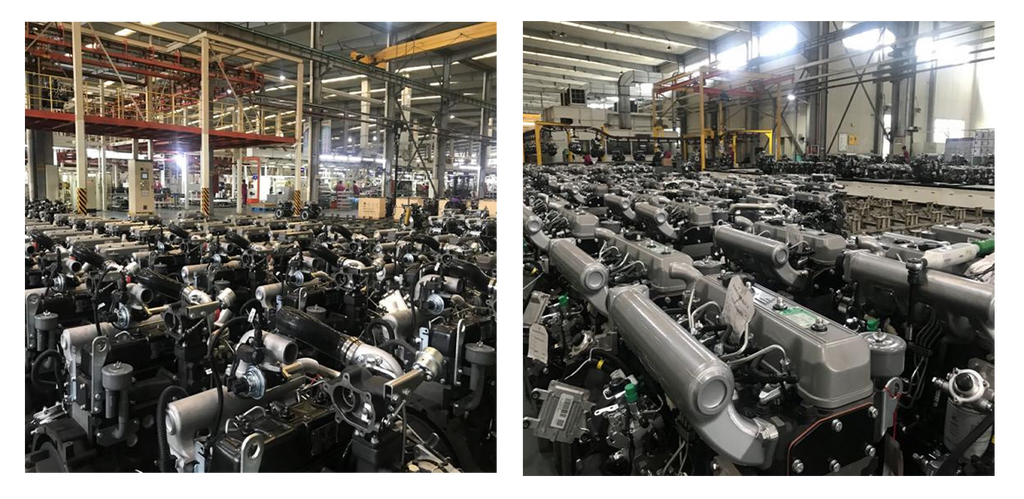

The annual production of these models is more than 200,000 sets with steady growth achieved for 10 consecutive years.

Engine Models:

- 4D4.8TAG2

- 4D4.8TAG3

- 6D6.5TAG2

- 6D9.7TAG1

Appearance baking paint, two-layer coating, wear resistance and scratch resistance, special anti-corrosion process.

The annual production of these models is more than 150,000 units, accounting for 70% of the market share of engines used in agricultural machinery and equipment, ensuring the stability of these models has been fully verified.

Engine Models:

- 6D10TAG1

- 6D10TAG2

- 6D12TAG2

Appearance baking paint, two-layer coating, wear resistance and scratch resistance, special anti-corrosion process.

The annual production of these models is more than 180,000 units, accounting for more than 50% market share of the heavy truck market. These models have been produced for more than 15 years, demonstrating the excellent performance of these classic engines to become a new-era product.

Engine Models:

- 6D13TAG3

- 6D16TAG3

Appearance baking paint, two-layer coating, wear resistance and scratch resistance, special anti-corrosion process

The annual production of these models is more than 80,000 units. PowerLink has been a leader in manufacturing engines for vehicles, power generation, shipping, professional engine manufacturing for more than 20 years.

Engine Models:

- 6KTAA25-G34

- 6KTAA25-G32

- 6WTAA35-G32

- 6WTAA35-G31

Appearance baking paint, two-layer coating, wear resistance and scratch resistance, special anti-corrosion process.

The annual production of these models is more than 60,000 units. PowerLink has been a leader in manufacturing engines for plant professional vehicles, construction machinery, power generation and shipbuilding industry leader, professional engine manufacturing for more than 30 years.

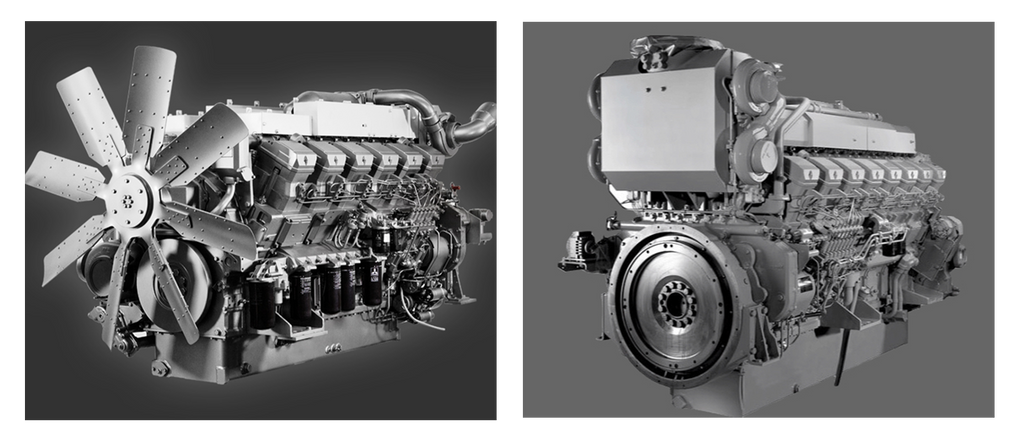

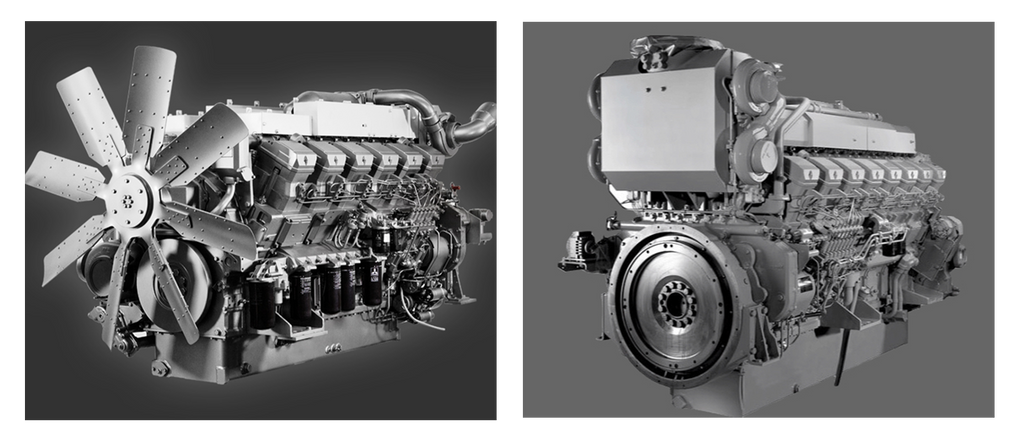

Engine Models:

- 12D39TAG5

- 16D52TWG4

- 16D52TWG5

Appearance baking paint, two-layer coating, wear resistance and scratch resistance, special anti-corrosion process.

The annual production of these models is more than 200,000 units. PowerLink has been a leader in manufacturing engines for vehicles, construction machinery, power generation and shipbuilding, and has been specialised in engine manufacturing for more than 20 years.

Engine Models:

- 16D65TAG3

- 16D65TWG2

- 16D65TWG3

Appearance baking paint, two-layer coating, wear resistance and scratch resistance, special anti-corrosion process.

The annual production of these models is more than 2,000 units. The factory is a leader in the field of ship power generation and professional engine manufacturing for more than 30 years.

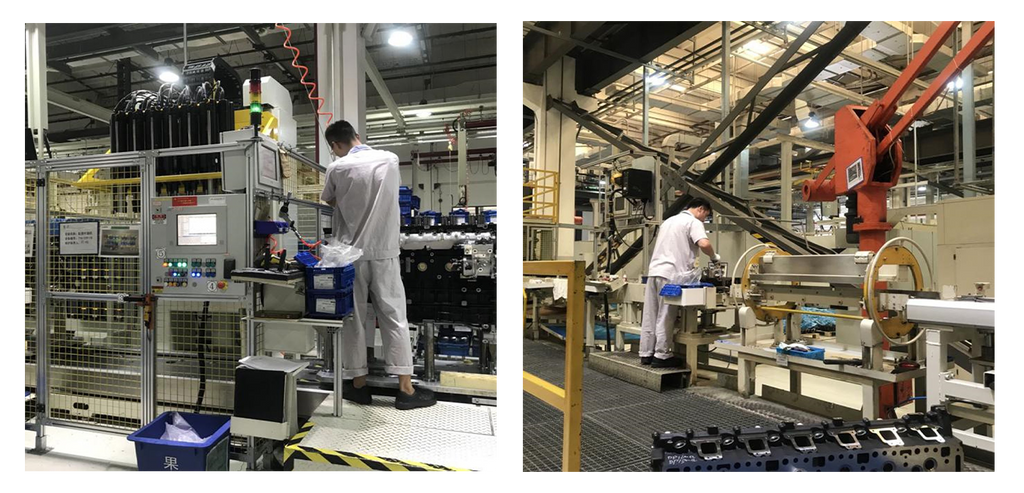

Engine Parts Line

Engine Block Line

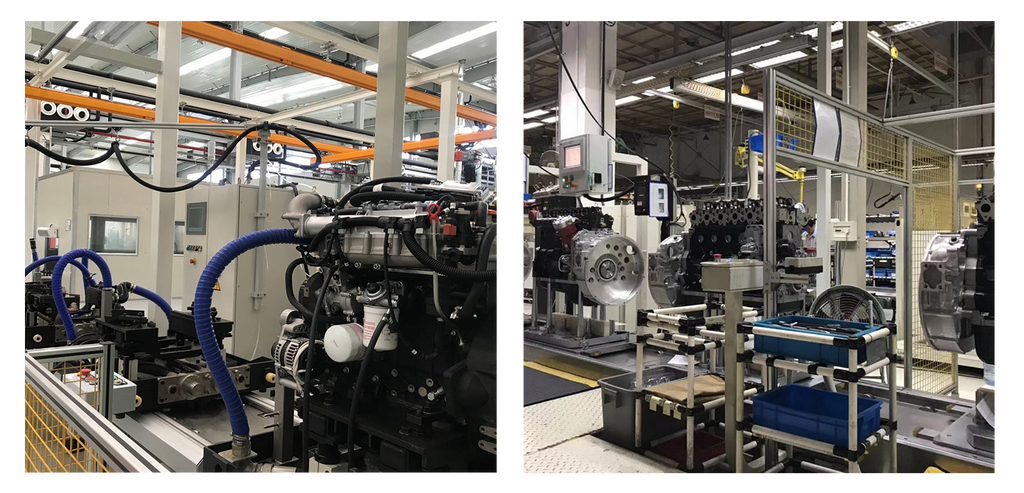

Finished Engine Line

PowerLink Alternator

Main features

The reliability of PowerLink’s Alternators is based on the high product standards of PowerLink and are incorporated in every stage of production - from materials used, manufacturing processes, through to any special requirements needed for environmental applications.

PowerLink Alternators reflect the continuous quality PowerLink pursues across its products. These requirements are not limited to:

- Ambient temperature of 40 ℃,

- Marine grade anticorrosion process,

- The copper quality of winding wire is specified by brand,

- Quality of silicon steel sheet, brand designation,

- Two times vacuum impregnation process,

- 2 / 3 winding pitch in accordance with G99 certified power output quality,

- Automatic voltage regulation AVR device, more than 500KVA standard configuration PMG, sudden increase and decrease load voltage fluctuation is not more than 1%

- Historical data of more than 50000 hours of stable operation.